Whilst digital printing is an exciting and continuously developing technology, screen printing is still a superior process depending on the material you’re using and the end result you want to achieve.

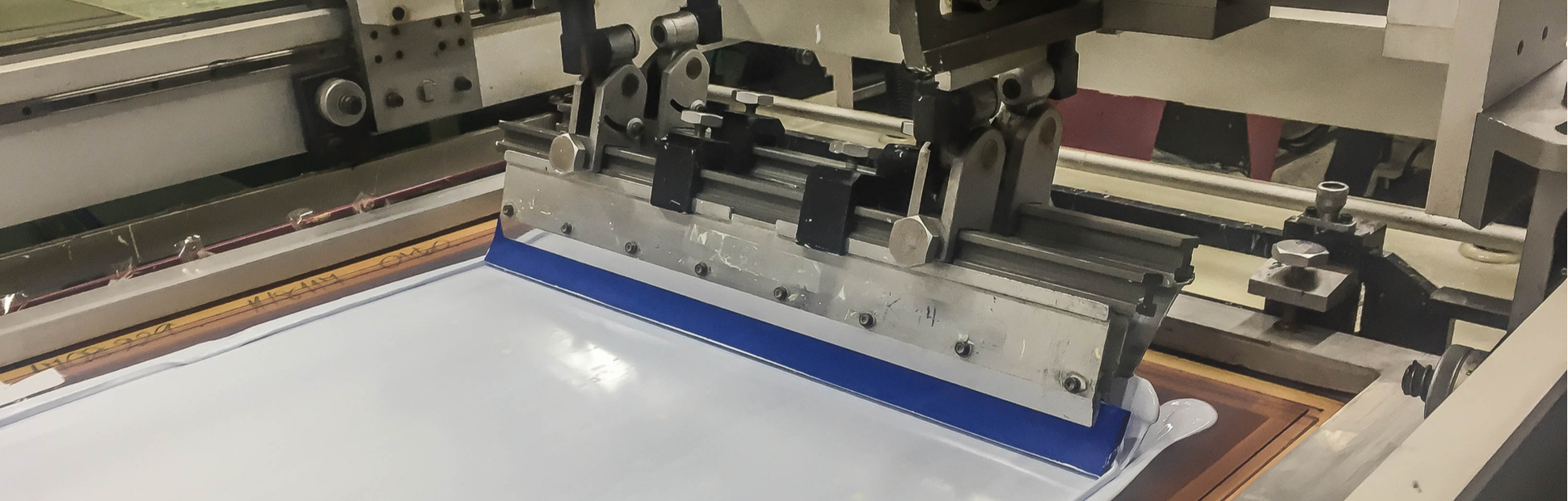

We work with both semi-automated machinery and manual hand-benches to combine many years of real experience with modern screen print production techniques. This allows us to realise all screen printing designs.

On this page we'll explain the screen printing process in detail; tracing its origins and evolution, as well as its advantages and disadvantages alike. We'll also provide our take on the screen printing vs digital printing debate, helping you settle on a preferred method.

From simple ink on paper for billboard posters, right though to multiple colours in the most demanding array of layered colour industrial overlays, we can work with you to screen print your needs.

Our screen printing process is incredibly flexible, and there is very little that we cannot screen print. Industrial labelling is a speciality of ours, and we've been manufacturing high quality labelling for over 30 years.

The following are all examples of products and materials that can be screen printed...

The enduring appeal of screen printing is testament to its quality, versatility and reliability. A process that originated in China as far back as the Song Dynasty era (960-1279 AD), serigraphy - as it is otherwise known - has evolved to transcend continents and generations alike and remain the most popular method of print for a host of commercial and retail applications.

The enduring appeal of screen printing is testament to its quality, versatility and reliability. A process that originated in China as far back as the Song Dynasty era (960-1279 AD), serigraphy - as it is otherwise known - has evolved to transcend continents and generations alike and remain the most popular method of print for a host of commercial and retail applications.

Screen printing gained significant traction in Asia long before Western Europe cottoned onto its potential in the late 18th century, and even then the phenomenon only truly began to make waves once silk mesh became more readily available through Eastern trade routes.

Three researchers credited with dragging printing methods kicking and screaming into the modern era are Roy Beck, Charles Peter and Edward Owens. Between them this trio experimented with chromic acid salt sensitised emulsions for photo-reactive stencils. Sound intense? It was. Nevertheless the triumvirate introduced photo-imaged stencils to the world, paving the way for the screen printing process as we now know it.

Mancunian Samuel Simon had the foresight to see where things were heading. He was granted an English patent covering screen printing in 1907.

Technological advancement meanwhile was such that by the 1930s distinctions could be made between artistic (serigraphy) and industrial variations and before long the sheer versatility of screen printing spawned mass production.

Movie posters, t-shirts, flyers, record covers, signage and more were all birthed and marketing methods the world over transformed.

Groundbreaking art and artists furthered the appeal. Andy Warhol popularised the technique, adopting Marilyn Monroe as his model of choice when creating a now iconic canvass in 1962.

Groundbreaking art and artists furthered the appeal. Andy Warhol popularised the technique, adopting Marilyn Monroe as his model of choice when creating a now iconic canvass in 1962.

Inspired by her untimely death, Warhol produced the Marilyn Dipytych – 50 images of the American actress, half of which are brightly coloured, the other much darker and hinting at sinister connotations.

In 2004 Warhol’s masterpiece was ranked third in a Guardian poll of the most influential art ever created.

He’s not the only creative to make his name on the back of screen printing designs however. The likes of Steve Harrington, Cody Hudson, and Deanne Checuk bring modernity to an age old method. Why? Because the process allows for imagination and experimentation, something they cherish. More and more designers are harking back to this approach, drawn to the uniqueness of the end product.

Refreshingly, perhaps reassuringly, mistakes and imperfections often add to the originality of a piece meaning nothing is ever lost.

Another attraction is the opportunity for artists to sell multiple limited edition prints without that big an overhead. 300+ years into the game, screen printing is certainly here to stay. And according to IBIS World study in 2012 it's actually ‘booming’.

So what exactly is screen printing and how are screen printing designs realised? In short it's a form of stencilling, but that leaves far too many questions unanswered.

Screen printing is the process of forcing ink onto a surface through a makeshift screen, thus creating a pattern.

In this instance the ‘screen’ is in fact made from a piece of mesh. That mesh can be formed from either a synthetic polymer like nylon or a very fine stainless steel wire.

Any mesh is typically stretched over a frame and held in place; a tensiometer may even be used to indicate the tension at any one time.

Next a stencil is formed as parts of the screen are blocked off, awaiting print.

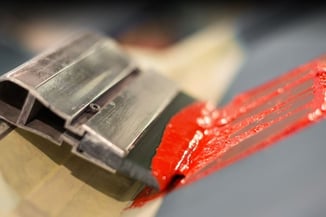

Screens are positioned on top of a substrate and ink duly coated across them with a sharp coating blade. Finally a rubber squeegee is used to push ink through holes created within the mesh itself, bringing designs to life.

A slightly different approach involves actual stencilling, this wherein a design is imposed upon a screen of polyester or similar mesh and its blank areas coated with an impermeable substance ink. This is forced into the mesh opening courtesy of a squeegee or fill blade.

In truth there of lots of different screen printing methods, though they all adhere to the same basic steps, which are...

We’ve certainly come a long way since the origins of screen printing. 2000 years ago the Chinese stretched human hair across a wooden frame to create their version of a screen. Stencils made from leaves completed this makeshift setup.

The Japanese created their own variation of the technique, one where woven silk was deployed as mesh and lacquers as stencils. This later became known as ‘silk screening’.

No matter the technique or machinery the end product can seemingly always be relied upon. Indeed a guarantee of quality is one of many reasons why screen printing designs remain the go-to for so many companies today. Make no mistake, it is still considered the industry standard for premium quality.

Another positive is its unique visual output. With screen printing ink is absorbed deeper, allowing for clearer edges to be assigned to any image. Similarly ink can be applied thicker – something that ensures a longer-lasting effect for both vibrant and darker shades alike.

When it comes to pricing meanwhile screen printing lends itself to big orders, for which it proves cost effective. Huge quantities can be produced in double quick time – with the turnaround for mass production a big draw for most clients.

Elsewhere printers are empowered to produce different types of products – be it banners, wallpapers, cylinders or caps – using the same screens. Again, this aids that all important productivity. Indeed screen printing is brilliantly versatile, accommodating any manner of materials – amongst them glass, fabric, vinyl, foam board, metal and more. Many are shocked to learn that the dials on watches are created this way, as too electrode strips for monitoring blood sugar levels. Really!

Screen printing designs, in most instances, are long lasting. When ink is bonded over garments it results in durable, clearer images compared to those created using digital printing.

Heat-dried screen printing meanwhile allows for repeat washing – the best clothing should neither run nor fade. It’s important to remember that additives and coatings can be applied to help with this. Such treatments are designed to make ink resistant to the likes of UV rays, scratches, chemicals and moisture.

Screen printing unquestionably remains the best option for garment design – which has always depended upon a high level of vibrancy when printing onto darker shades.

To summarise, the advantages of screen printing are as follows:

As with any process, there are drawbacks. It’s not always practical to buy in bulk – but smaller orders and those made on demand can be difficult to accommodate. What’s more expenses can spiral with an increase in colours. Sadly the more tones a design encompasses, the greater your outlay.

Furthermore despite best efforts screen printing is not all that eco friendly. Endless amounts of water are mixed up with inks and – given the hundreds of thousands of garments produced daily across the globe – this adds up. While plastisol inks and water based inks may be deployed, these are not as sustainable as the polymer-based equivalent.

On balance however the screen printing process is looked upon favourably and has certainly stood the test of time. It’s reliable, economical, versatile and generally straightforward, hence it’s enduring appeal.

Before embarking upon a screen print it is of course vital to decide what mesh screen to call upon. A mesh size is measured by how many threads of mesh there are crossing per square inch. Typically the higher the mesh count, the finer the threads and holes you have to work with upon the screen.

So when it comes time to decide, consider how detailed an image you require and how thick the ink with which you plan to create it.

110 and 156 are recognised as the standard mesh sizes. The former is particularly useful when creating block text letters or larger spot colour designs – this due in part to its thicker layer of ink.

A 156 mesh meanwhile, though laying down similarly thick ink, facilitates higher detail.

When it comes to mesh screen selection it’s important to guard against non-compatibility. A lower mesh for instance is unlikely to hold highly detailed images due to fine lines falling through its bigger holes – thus soaking the substrate.

As a general rule of thumb 40-86 tend to suit shimmer and glitter ink prints, 200-230 lend themselves to finer detailed images and thinner inks, while 305+ is the mesh of choice for those creating products that are extremely detailed.

Any higher and you’re entering the world of graphic printing and UV inks – extremely thin and detailed outputs utilised for road signs, banners, CDs and more.

Those new to the industry are often left wondering what the difference are between screen versus digital printing, or whether there’s a difference at all.

Those new to the industry are often left wondering what the difference are between screen versus digital printing, or whether there’s a difference at all.

As highlighted above screen printing is a traditional method that involves stencilling and the application of layers of ink onto a selected print surface. By contrast, digital printing is far newer and utilises a computer to process the artwork slated for print. Consideration should be given to what images are suitable for screen printing and which would lend themselves to the newer of the two processes.

Indeed much of the work traditionally associated with screen printing designs can now be realised digitally.

In fact items that necessitate high amounts of detail are perhaps better delivered in this fashion. The absence of a screen facilitates photographic print and with it sharper images. Shorter runs meanwhile are also possible due to digital’s economic viability. Whereas before the sheer effort of setting up screens almost demanded printing in bulk, digital enables a single item to be created with minimum fuss.

Another key differentiator is the fineness of inks deployed. Thinner types are associated with digital prints, thus generating the aforementioned extra detail. Unsurprisingly, thicker alternatives are found in screen printing designs, though this has been known to produce brighter colours on even dark backgrounds.

Budding artists unfamiliar with screen printing practices or unable to access machinery commandeered by professional printers need not be discouraged. Indeed screen prints - or at least some version of them - can be produced at home.

The DIY approach requires a checklist of materials. These include the following:

Not forgetting access to a darkened room, which will prove vital in the process explained below.

Once everything has been collated the illustrator should create their image in Photoshop or the equivalent of. Keeping things simple is advisable, at least initially. On completion this design should be printed onto transparent paper.

Moving forward you will have to mix sensitiser and emulsion, doing so according to the instructions on the back of their respective bottles. This mixture will duly be poured onto a screen, one ideally placed onto a rubbish bag. Use the aforementioned squeegee to spread the liquid evenly. A wait of two hours then sets in, as you leave your screen in a darkened room.

On your return you should the screen should be exposed to light – a lamp shade will suffice. Lay down a black cloth or board, onto which you should then place your screen and frame – screen side down. From here you should position your transparent image, taping it down with low-tack masking tape or glass if you prefer. Point light directly at the image for a further 15 minutes. If all goes to plan you should then lift your transparency to unveil faint blue lines – these formed as a result of your image burning onto the screen.

A clean-up operation will then ensue. Wash your screen until the image displays clearly. On drying cover any exposed areas that do not contain photo emulsion or your image with the same masking tape used earlier. Clear tape can be added but beware this has been known to leave a sticky residue.

Finally, the big pay off...

Lay your shirt onto a flat surface, stuffing cardboard beneath the area reserved for print. Place your screen over the shirt and begin to tip ink horizontally across it. Pick up the squeegee once again to spread the mix firmly and evenly. Continue the motion until ink is pushed through onto your shirt. With a little luck you will have created your first printed t shirts.

Those hoping to produce longer lasting items/prints swear by a ritual of placing the shirt in an oven for 30 seconds at this point. Try it out.

Can screen printing screens be re-used? In a word, yes. In fact you do not necessarily need to remove the emulsion; a simple wipe down at the end of the day will have the desired effect. Screen cleaner can be purchased from the same place you picked up your emulsion.

In theory, your burned image should last a good while. In some instances years. Better still, there is less of a need to clean if you intend to use the same colour each time.

Given the information shared above it will come as no surprise to learn that one of the primary applications of screen printing designs is in the textile industry. Put simply, the method uses more ink than other printing processes – such as digital. Moreover that ink is pushed into the fibres of fabrics, creating a longer lifespan for clothing in particular. Designs, patterns, slogans and more can be realised and the likes of t-shirts, hoodies and dresses brought to market. Those wanting to produce big quantities meanwhile benefit from relatively low prices.

Block colour designs with text are widespread across the tourism industry also. Screen printing’s flexibility essentially allows you to print onto anything at a reasonable rate. Market stalls tap into that, stocking the likes of bags, hats, coasters, flags and more in a bid to attract holidaymakers. The versatility afforded here is simply not possible by other means.

Elsewhere overlays and fascias are commonplace in the electronic and automotive sectors. You will see examples on the likes of control panel covers. Though digital printing is very much an option for producing such materials screen printing is better suited for specific and/or varying textures. What’s more complex shapes, clear windows and even anti-glare coatings can be created this way, guaranteeing legibility.

Finally window displays are often reliant on screen printing methods. Bright colours are better realised, while clear and opaque window decals prove durable if created in this manner. Think office space, storefront’s and more. Screen printing helps companies market without haemorrhaging funds.

Units 2 & 4,

Little John's Lane,

(Albury Close, off Loverock Road)

Reading,

Berkshire,

RG30 1RA

Copyright © 2024 Evans Graphics Limited | Company number: 01912806

Powered by Intergage