Sticker printing remains as popular today as it ever has and is used to great effect on the high street, within classrooms and upon vehicles.

Evans Graphics have great experience producing simple but impactful stickers, screen and digitally printing these items to any shape or size, on to any number of different materials.

Our customers can choose between self-cling PVC, self-cling vinyl and more, with a growing number requesting large print runs.

Clear stock can be reverse printed and applied to the inside of windows, allowing messaging to be read from the outside. It can also be produced using solid white materials.

If preferred, clear stock can be added to the outside of a window itself or indeed any solid surface, making for a conventional sticker like the bumper variety seen on cars.

The enduring appeal of these products is one easy to understand.

Large window stickers are a cost-effective way of attracting footfall into shops and businesses. Micro decal lends itself to promotional items, such as the die-cast model car pictured below. Others simply want to produce decoration for lockers, lunchboxes, notebooks and the like.

Anyone hoping to make an impact without breaking the bank would be well served to investing in sticker printing.

Accessibility Controls

The player supports TAB to change the controls.

Update Required<br/>To play the media you will need to either update your browser to a recent version or update your <a href='https://get.adobe.com/flashplayer/' target='_blank'>Flash plugin</a>.

We are the trusted partner to your creative expression, ensuring that your design intentions shine through. Just as you imagined.

Whether it’s in the form of a free-standing display, signage or standee, these easily printed marketing assets deliver a huge impact for a low cost.

We offer both indoor and outdoor materials which can be easily wall mounted or used as free standing signage.

Our exhibition graphics are printed on high quality materials and can be finished in a variety of ways.

Magnetic printed materials can be fitted to vehicles as a means of advertising on the road.

We’ve been producing high-quality, high-impact signs for over 30 years. Everything from storefronts to POS.

Stickers are as popular as ever. Used to great effect on the high street, in classrooms and vehicles.

Full colour window graphics are a great way to brand any office or retail window, be it with company logos, designs or strap lines.

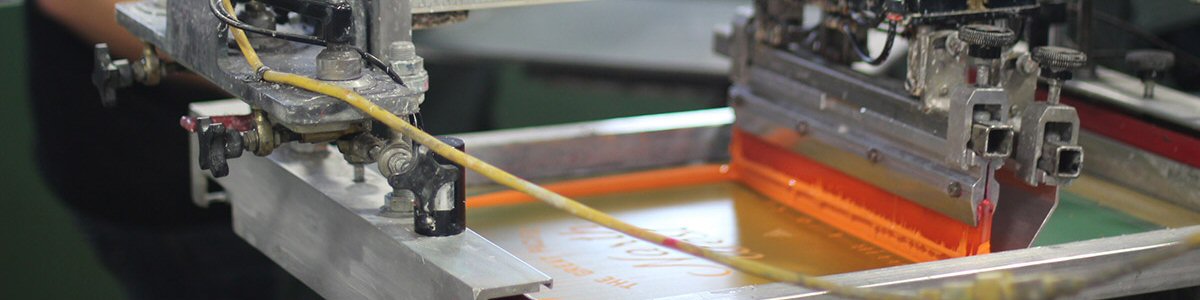

Screen printing stands out from other printing process as being one that requires a more hands on approach. While there is an automatic screen printing process as well as a manual one, there is still an air of craft about it that is truly unique.

There are a lot of variables, and in order to get the best results from this technique the following must be considered and factored into your own processes.

One element of the process that can’t be underestimated in importance is the quality of your equipment – but with the focus on how you are able to set it up. A low cost, low option press will enable you to create a print, but the quality of that print will be limited by the capabilities of that press.

This is because improper set-up is the reason behind most production problems, and ability to fine tune the press will allow to you correct problems quickly. Keeping a record of these settings for each task will then allow you to achieve consistent results over multiple runs.

Controls that allow you to alter the numerous variables of set-up should be high on your list of desirable features:

If you’ve invested in a better quality press, you’re also going to want to ensure you keep it in optimal condition to realise the return on it.

The single most important thing you can do is to keep the press clean. Taking care not to unnecessarily soil the machine in the first place is a good start, but it will inevitably accumulate dirt and grime which should be cleaned often and as part of a regular maintenance schedule.

A good habit is to check the machine during each run to pick up on anything that may have come loose or even broken. This will improve the quality of your prints by catching loose screens, and also prevent excessive wear on parts that aren’t correctly in place.

Take care of your tools and they will take care of you.

Ink – With the number of variables governed by ink choice being so great, the choice of ink will have a large effect on the end result; viscosity, surface tension, size of pigment particles, solvent

evaporation rate, operating temperatures, and shear are all factors to consider.

Whether or not to use UV ink will be the main decision that has to be made. You don’t have to worry about drying times with UV ink – but on the other hand you must protect them from UV light sources before they are ready to be cured e.g. sunlight. Otherwise they could start to cure prematurely.

Screen/Stencil – The type of screen used will have an effect as more complex and detailed designs will benefit from higher mesh counts and finer threads. The standard 110 count screens will handle

most tasks, but can struggle to produce what a fine 400 count screen is capable of.

The quality of the screen will also have an impact on the quality of print produced. Higher tension screens need less pressure and thus less effort to deposit ink. This is of critical importance on a manual press where that difference impacts directly onto an operator, but is also relevant to an automatic press where the it allows for less off contact distance and a faster registration time.

Squeegee/Blade – Being responsible for bringing the ink into contact with the substrate, this is another element that will have a noticeable effect. Blade hardness (or durometer) is a key consideration which should be determined by the surface of the substrate. Softer blades are suitable for uneven surfaces but are generally less durable and degrade - harder ones should be used where possible.

For manual presses, anything that will affect the operator is also a consideration; flexibility, length, angle, speed, pressure, height etc. Whatever makes it easier to operate will maintain consistency of the print by limiting fatigue.

When it comes to the act of printing itself, experienced operators will have honed their skills over a long period of time, and built their knowledge through trial and error across a variety of tasks.

There will no doubt be some debate over what that exact best process is and will be based on the individual and their own personal experiences - likely governed in some part by the peculiarities developed by the combination of equipment and tools they have used.

When establishing your own technique these are some of the things to consider:

By following these guidelines you can create an effective process that produces professional results to benefit on you and your customers. Or at least pick up a few points you may not have considered before to help improve your technique.

Contact us today to discuss your print project with a member of our team.

Copyright © 2024 Evans Graphics Limited | Company number: 01912806

Powered by Intergage